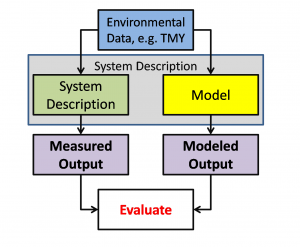

The objective of performance modeling is to predict the expected output of a solar system given 1) the system design, and 2) the environment in which it is operating, including the solar resource. A performance model is actually a collection of submodels, which calculate different quantities needed for determining output power. Validation of these modules involves comparing model predictions to high-quality measured data.

The level of detail required for the environmental data, the system description and the measured system data varies depending on the objectives of the validation effort and the detail contained in the model to be evaluated. In all cases, however, the environmental and measured system data must be:

- easily retrievable

- consistently time stamped (to allow correlation of environmental and system data)

- free of flaws and inconsistency (scrubbed)

| Design Data Requirements (increasing) | Model to be validated (increasing complexity) |

| Location, orientation, tracking, STC rating | System Performance Factor (SPF) |

| Module type (γ), inverter efficiency, soiling estimate, shading estimate, dc and ac loss estimate | PVWatts |

| Mounting | CSI EPBB calculator |

| Modules/string, string/array, inverter number and type, shading details, row spacing | System Advisor Model (SAM) |

| Wiring lengths, module orientation, wiring configuration, monthly soiling, ac losses | PVsyst |

| Environmental Data Options | Impact |

| TMY | Compare to expected SPF, subject to interannual variability |

| Satellite | Subscription fee, no local sensors, not well validated, likely adequate for monthly comparison |

| Reference Module* | Validate PV performance models without any other environmental sensors, but not irradiance or module temperature models |

| Plane of array*and weather sensors | Validate PV performance, module temp models |

| Global horizontal irradiance* and weather sensors | Adds uncertainty in translation models |

| GHI*, DNI* and weather sensors | Full comparison to TMY dataset, High Cost |

*regular cleaning desirable